All-State Industries is a leader in custom-engineered, plastic components. As metal replacement experts, we can show you how high-performance plastics can improve part life, reduce wear on mating surfaces, decrease corrosion and reduce or eliminate lubrication. From simple wear strips to high-speed bushings, All-State has the solution for your component requirements.

OUTFITTED WITH THE INDUSTRY’S LATEST PLASTIC MACHINING TECHNOLOGY

All-State utilizes state-of-the-art equipment and advanced compounds to deliver high-quality parts for your application. Our experience in component design enables us to select the proper material, machining process and initial stock shape to meet the performance, tolerance and cost requirements of your parts.

QUALITY MACHINED PLASTIC COMPONENTS FOR A RANGE OF INDUSTRIAL APPLICATIONS INCLUDING BUT NOT LIMITED TO:

-

Abradable shrouds

-

Back-up rings

-

Bearings & bushings

-

Cams & cam followers

-

Chain guides

-

Custom fixtures & housings

-

Gears, sprockets & pulleys

-

Insulators

-

Labyrinth seals

-

Manifolds

-

Nozzles

-

Rollers & rotors

-

Sheaves & sleeves

-

Slider beds

-

Valve seats

-

Wheels

-

Wipers

-

Wear pads

WE ARE THE EXPERTS IN CUSTOM-MACHINED PLASTICS

All-State Industries is a leader in custom-engineered plastic components. We can optimize both the quality and performance of your custom parts with our high-performance plastic materials and streamlined manufacturing solutions.

Our precision machined plastics reduce wear on mating surfaces, decrease corrosion and reduce or eliminate the need for lubrication. From simple wear strips to high-speed bushings, All-State has the solution for your component requirements.

ALL-STATE INDUSTRIES IS YOUR ONE-STOP SHOP FOR CUSTOM-MACHINED PLASTIC PRODUCTS

All-State Industries provides components machined from a wide variety of high-performance plastic materials. Milling, turning, routing and sawing are done on state-of-the-art CNC equipment, some of which is fully robotic.

Our focus is on wear applications such as bushings, slide pads and gears. We provide the technical assistance you need for material selection and part design parameters. Prototypes or production runs, basic or exotic materials, old parts or new designs, All-State provides solutions for your plastic requirements.

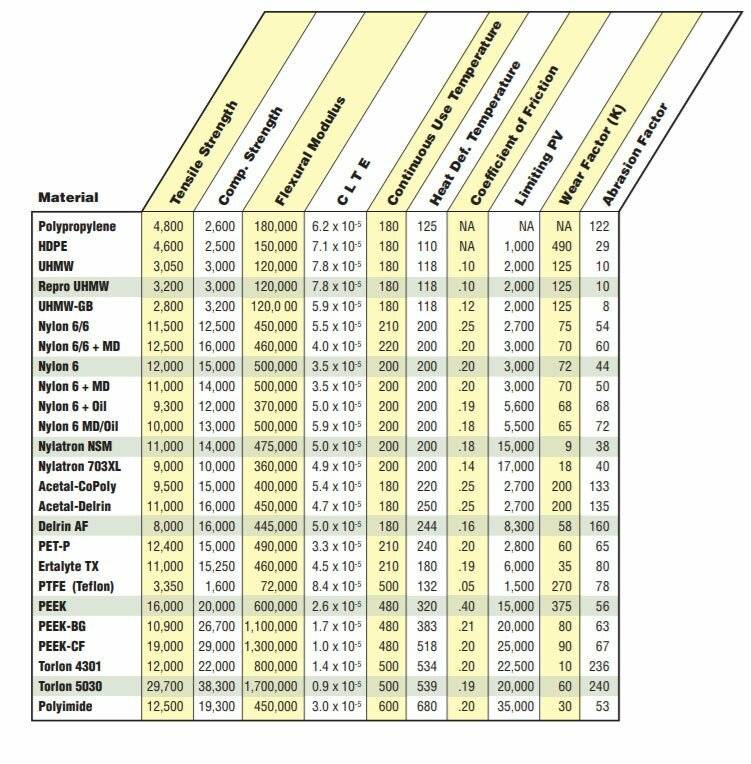

PLASTIC MATERIAL PROPERTY CHART

Use our convenient chart to compare the different material qualities of the premium plastics we utilize at All-State Industries. We provide material expertise with an array of plastics, each offering unique levels of rigidity, stiffness, abrasion resistance and wear life, as well as a huge range of optimum operational temperatures.