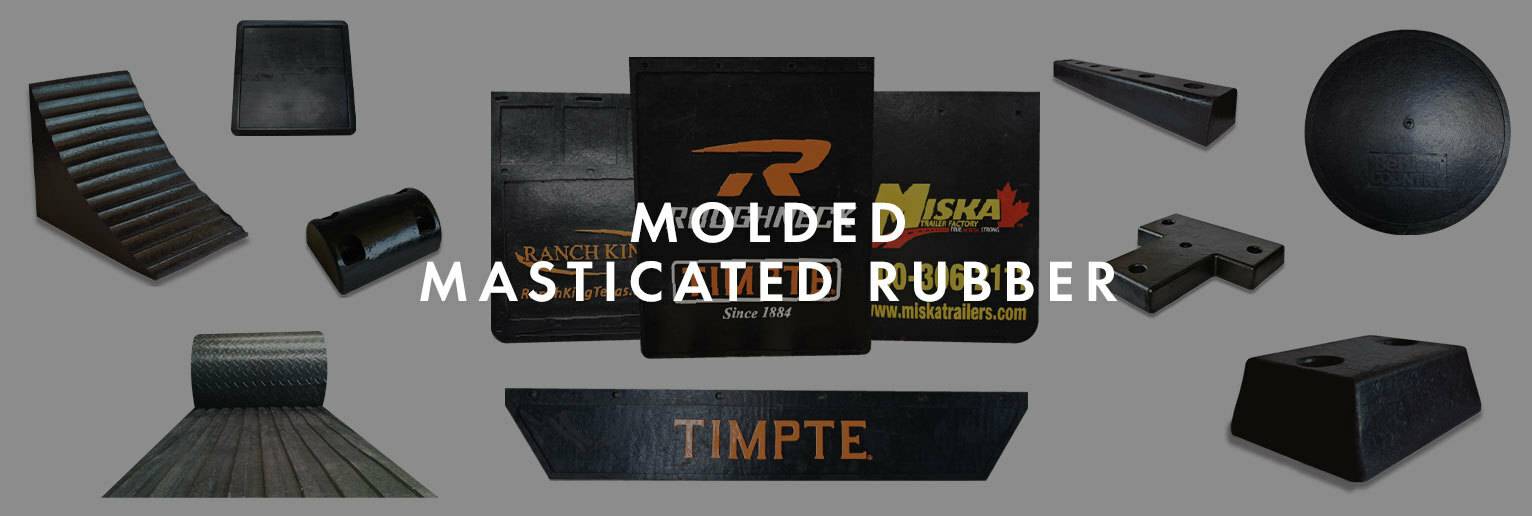

Look to All-State Industries for all of your industrial, molded-rubber components manufactured with our premium, high-grade masticated rubber.

WHAT IS MASTICATED RUBBER?

Masticated Rubber is a rubber compound made from reclaimed/recycled synthetic or natural rubber. In All-State’s case, we recycle pre-consumer tire friction waste, sourced from various tire manufacturers in North America.

Utilizing quality masticated rubber as a raw material ensures our molded products are of premium, consistent quality, while also being cost-effective and environmentally sound.

THE BENEFITS OF MASTICATED RUBBER PRODUCTS

Masticated rubber is your economical choice for molded rubber applications where tensile strength, durability, UV/weather resistance, bolt retention and abrasion resistance are must-haves. We achieve the durability that we do because of the inclusion of the nylon and/or polyester fabric reinforcement used in the production of tires.

VERSATILE MASTICATED RUBBER MANUFACTURING SOLUTIONS

All-State Industries produces a variety of economical, industry-standard components as well as custom-molded components for OEMs and end users all over the world. Located in Irapuato Mexico, our molded rubber manufacturing facility takes pride in creating solutions including but not limited to:

MUD FLAPS

All-State Industries offers some of the toughest mud flaps in the industry. We have an extensive line of generic splash guards taking into account the most popular styles, sizes and bolt placement in the U.S. We can also customize your mud flaps by adding high-quality, highly visible, single- or multi-colored company logos to give your branded products that extra flair.

All-State provides our customers the ability to choose from over 20 mud flap styles, typically ranging from ¼” thick to ½” in standard sizes. Whether you need generic chevron flaps to customized company logo flaps, we do it all.

The logos of our mud flaps extend beyond the surface of the flap itself. The paint used for color logos is of the highest quality, specifically formulated for outdoor applications. We’re also capable of molding wire mesh into most mud flaps to add some needed rigidity for certain environments.

We can incorporate standard anti-splash/anti-sail features into the back of your flaps as well. Remember, if you don’t see exactly what you need in our style guide, please reach out to us and we can talk through customizing your precise sizes, thicknesses and bolt patterns, as well as front and back styles.

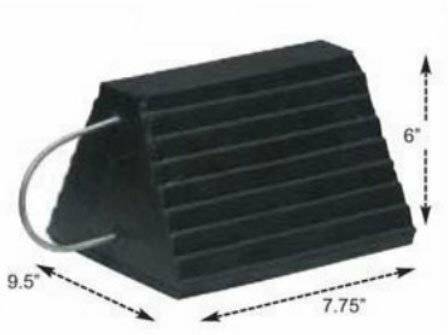

WHEEL CHOCKS AND TRUCK, TRAILER & DOCK BUMPERS