All-State Industries delivers a complete range of innovative, non-metallic industrial manufacturing services, including custom-cast, polyurethane solutions.

Urethane is a high-performance engineered elastomer. It offers superior characteristics for high-demand applications. Urethane is known for its excellent properties of abrasion resistance, cut and tear strength, load bearing, shock absorption and chemical and environmental resistance.

THE BENEFITS OF CAST POLYURETHANE – VERSATILE & RELIABLE CUSTOM MOLDING SOLUTIONS

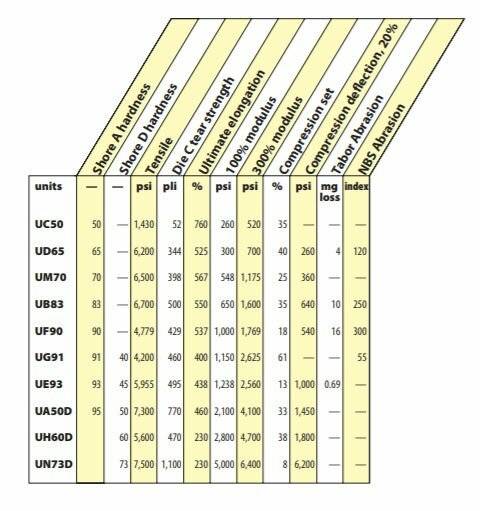

In addition to being a top choice in demanding applications, urethane has other characteristics that make it a viable option in a variety of non-traditional applications. It is available in a wide range of hardnesses – from very soft, like a rubber band, to very hard like a bowling ball – and in several different colors.

All-State molds all of your custom-cast, polyurethane parts in-house, accommodating both simple and complex component designs. We have the capability of bonding urethane to different materials including steel, aluminum and plastic to enhance performance characteristics.

PREMIUM CAST POLYURETHANE COMPONENTS FOR A DIVERSE RANGE OF NON-METALLIC INDUSTRIAL APPLICATIONS

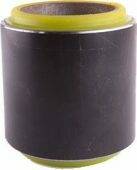

ENGINE BUSHING

Application – Cast polyurethane heavy truck bushing used to isolate vibration from the engine and transmission compartment on a large wheel loader, reducing NVH for drivers while improving drivetrain efficiency.

-

Higher load-bearing capability over rubber

-

Urethane molded ID of bushing, outer sleeve is pressed on afterwards

-

Low hysteresis build-up

-

Dampening properties tuned to application

FUEL FILTER

Application – Quality polyurethane fuel filter for an industrial diesel engine.

-

Replaced PVC seals on the ends of the filter due to cracks that were caused by hot fuel exposure degrading the PVC

-

Excellent resistance to fuel and chemicals

-

Urethane molded to a steel mesh screen

RETURN WHEEL

Application – Cast polyurethane wheel for a commercial bowling ball return machine.

ARM REST

Application – Custom ergonomic armrest for industrial forklift applications.

-

Soft-touch foam pad with abrasion-resistant polyurethane skin

-

Foam bonded to steel plate

-

Different colors available through in-mold painting

HOOD GUIDE PIN

Application – This premium cast polyurethane hood guide pin is used to securely position the hood on a heavy truck and isolate vibration in the hood structure to reduce road noise and improve aerodynamic efficiency.

-

Replaced rubber because of increased wear life

-

Bonded to a painted metal bracket

-

High cut/tear and abrasion resistance

SEAL BOOT

Application – Reliable cast polyurethane seal boot that prevents dirt from getting into the boring head of drills, protecting the internal components from damage while substantially improving the service life of the tool.

-

Improved abrasion and cut/tear resistance over rubber

-

Complex shape molded as one piece

-

Ability to compress when needed

-

Material stays flexible over a wide temperature range

BOOM REST

Application – Custom cast polyurethane boom rest for aerial trucks.

-

Good load bearing capability

-

Steel inserts can be molded into boom rest to increase load bearing capability

-

Isolation of boom from impact when in transit

-

Can take impacts/deflects when hit with the boom

-

Non-marking

HVAC AIR INTAKE ADAPTOR

Application – Intake hose adaptor for air management.

-

Material hardness similar to rotomolded or blow molded PE

-

High heat deflection – 300F

-

Complex shapes can be molded